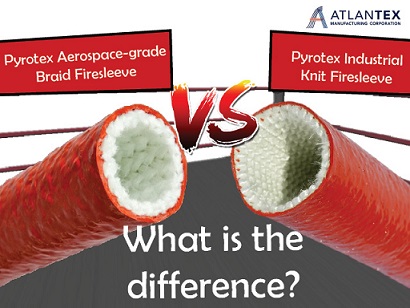

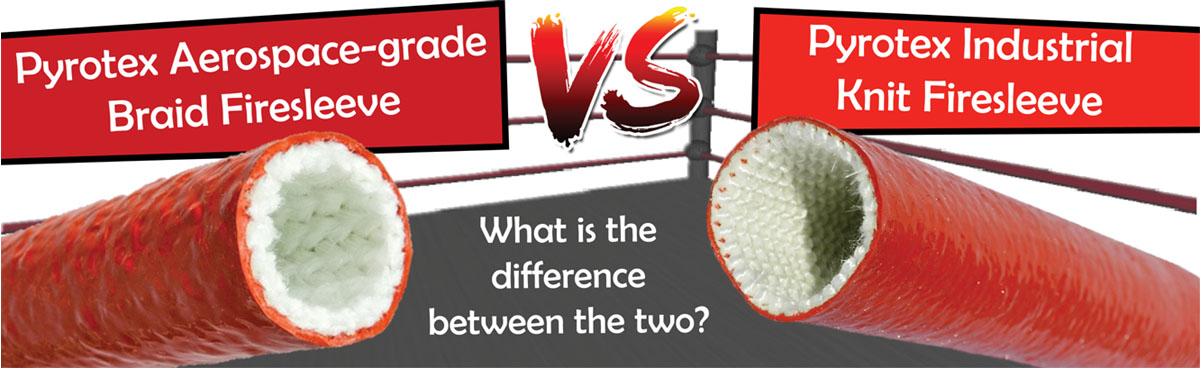

The main difference between the Aerospace-grade and Industrial grade Pyrotex is the construction of the fiberglass layer and the amount of fiberglass used in the layer. See the differences and similarities below.

PYROTEX AEROSPACE-GRADE BRAID FIRESLEEVE

- Utilizes more fiberglass in substrate and more silicone in coating

- Braided E-Glass substrate offers 100% glass coverage

- Largest size range available (1/4” to 6” ID)

- Increased insulation performance

- Maintain internal temperature for heated lines

- Protects cool lines from external heat & damage

- Premium firesleeve carries third-party certifications

- UL 1441 with VW-1 Flame Rating

- AS1072 compliant for AS1055 assemblies

- Best suited for the following applications:

- High ambient heat, heated lines, personnel protection

- Automotive and transportation applications

- Heated or heat-traced lines

- Marine, aviation, construction, and defense equipment

PYROTEX INDUSTRIAL-GRADE KNIT FIRESLEEVE

- All-purpose firesleeve suitable for use in many applications and environments

- Longest continuous lengths for scrap reduction

- Best pricing for silicone-coated sleeving

- Lighter-weight than braided firesleeve = reduced finished weight of assembly

- Best suited for the following applications:

- General industrial hose/line protection

- Mill & Foundry applications

- Welding applications

- MRO applications

- High ambient heat & molten splash

BOTH PRODUCTS

- Same temperature rating (minimum and maximum) for both glass substrate and polymer coating

- Same self-extinguishing and molten-splash resistant coating

- Available in RIO, Aluminized, Black, Yellow, Blue, Red, and Green

- Materials comply with REACh, RoHS, and Conflict Minerals requirements

- Can be fabricated with Velcro®, Zippers, or Snap closures

- Resistant to high temperature, common industrial/automotive fluids, and UV/weathering

- Can be terminated with SA Tape or Pyrotex End Dip

- Excellent flexibility across size and temperature range

- Elasticity allows sleeving to be stretched over fittings or irregular profiles

- Can be custom-printed for brand recognition or system identification

- Create refractory crust upon flame impingement to self-extinguish and minimize thermal transfer

- Substrate and silicone polymer developed and produced in-house directly by Atlantex

- Stocked product for fast turnaround / order fulfillment

- Bulk lengths, cut pieces, shop spools, and custom packaging available

- Atlantex produces both in-house and operates ISO 9001:2015 Quality Management System

Have any additional questions? No problem, we are here to answer them. Ask today by giving us a call at (610) 518-6601 or email us at CustomerService@atlantexmfg.com