ABRASION SOLUTIONS

Environments where system protection is your number one concern, Atlantex Manufacturing abrasion products are designed to provide long-wearing abrasion protection for hoses, lines, cables, and wires.

NYLON

TUFFTEX W

TUFFTEX W

Tufftex W is designed to provide long-wearing abrasion protection for hoses, cables and wires. Manufactured from high tenacity multi-filament Nylon yarn and woven into a flexible tubular sleeving, Tufftex W provides complete system coverage and reliable protection. The woven construction provides for an easy means to protect, bundle and manage critical… Read more

NYLON CLOSURE OPTIONS

TUFFTEX HLC

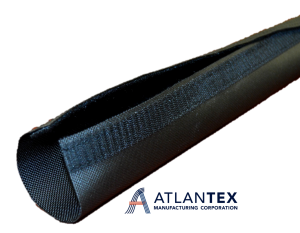

TUFFTEX HLC

Tufftex HLC provides an easy-to-install abrasion protection and line bundling solution, ideally suited for many applications and industries. Manufactured with a specially-coated 1050-denier ballistic Nylon and an industrial-strength hook & loop closure system, Tufftex HLC provides long-wearing, yet flexible and lightweight, system protection… Read more

TUFFTEX SNAP

TUFFTEX SNAP

Tufftex SNAP provides an easy-to-install abrasion protection and line bundling solution, ideally suited for many applications and industries. Manufactured with a specially-coated 1050-denier ballistic Nylon and a stainless steel snap closure system… Read more

TUFFTEX ZIP

TUFFTEX ZIP

Tufftex ZIP provides an easy-to-install abrasion protection and line bundling solution, ideally suited for many applications and industries. Manufactured with a specially-coated 1050-denier ballistic Nylon and a heavy-duty Nylon zipper closure system, Tufftex ZIP provides long-wearing, yet flexible and lightweight, system protection which can be installed in the field… Read More

PROTECTIVE SPIRAL WRAP

SPIRAL GUARD WRAP

SPIRAL GUARD WRAP

Spiral Guard Wrap is an economical and convenient method of extending the life of hydraulic and pneumatic hoses, cables, wires and rope. Manufactured from extruded high density polyethylene (HDPE), Spiral Guard Wrap will withstand the extremes of climate and operating conditions and protect components from premature wear, cutting, and crushing. The HDPE extrusion… Read more